The price of setting up a keyless door lock in West Palm Beach, FL can differ depending on factors. Here are some aspects that may affect the cost; Variety of Keyless Lock:door locks come in types, such as electronic keypad locks, smart locks with Bluetooth or Wi Fi connectivity and biometric (fingerprint) locks. The cost… Continue reading How much does it cost to install a keyless door lock?

Can a locksmith open all locks at Bar Harbour FL?

Locksmiths who are professional locksmith have the training and tools to handle types of locks. There are limitations based on factors, like lock complexity security features and legal requirements. Here are some important points about locksmiths and their ability to open locks in Bal Harbour, FL; Types of Locks:Locksmiths can usually open locks such as… Continue reading Can a locksmith open all locks at Bar Harbour FL?

How long it take for locksmith to open a car?

The time it takes for a locksmith to open a car in Miami Beach can vary depending on several factors: In general, professional locksmiths aim to provide timely and efficient services, especially in emergency lockout situations. If you find yourself locked out of your car in Miami Beach, consider contacting a reputable locksmith with a… Continue reading How long it take for locksmith to open a car?

Can a locksmith make a key out of a lock?

Yes, a locksmith has the skills and tools to make a key from a lock, a process known as key impressioning or key decoding. Here’s how it typically works: It’s important to note that this process requires skill and experience, and not all locks are easily impressionable. High-security locks or those with complex mechanisms may… Continue reading Can a locksmith make a key out of a lock?

How do locksmiths get into locked car?

Locksmiths use a variety of techniques and tools to gain access to a locked car in Fort Lauderdale, FL, or any other location. It’s important to note that professional locksmiths follow ethical and legal practices when providing car unlocking services. Here are common methods used by locksmiths to unlock cars: It’s important to highlight that… Continue reading How do locksmiths get into locked car?

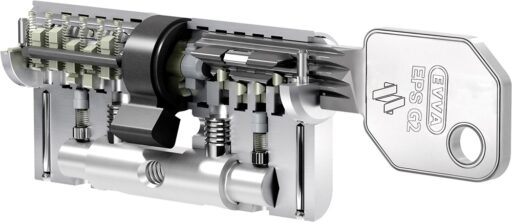

Which High-Security Keys Can Be Duplicated, Which Can’t, and Why It Matters.

Understanding Restricted and High-Security Keys Not all keys are created equal. While standard keys can be easily duplicated at most hardware stores, high-security and restricted keys are designed with features that make unauthorized duplication significantly more difficult. In Boca Raton, Davie, South Beach, and across Florida it’s not impossible to replicate any lock or key… Continue reading Which High-Security Keys Can Be Duplicated, Which Can’t, and Why It Matters.

Is losing a house key In Boca Raton FL IS a big deal?

Losing a house key can be a cause, for concern in any location including Boca Raton, FL due to the security implications. Here are some reasons why misplacing a house key can be seen as a problem: Security Concerns-If your misplaced key ends up in the hands it could pose a security threat to your… Continue reading Is losing a house key In Boca Raton FL IS a big deal?

Can I rekey my own locks in Sunrise FL?

Sure you have the option to change the keys for your locks in Sunrise, FL if you have the tools and know how. Rekeying a lock involves adjusting the pins or tumblers to fit a key while keeping the existing hardware intact. Here’s a basic guide on how to rekey a lock on your own… Continue reading Can I rekey my own locks in Sunrise FL?

What to Do If You Are Locked Out of Your House in West palm beach?

If you ever find yourself locked out of your house, in West Palm Beach here are a steps you can try to get inside your home: Stay Calm-While it can be quite stressful to be locked out its important to try and stay calm. Getting panicked might make it harder to think clearly. Look for… Continue reading What to Do If You Are Locked Out of Your House in West palm beach?

What does an emergency locksmith do?

An Emergency locksmith in West Palm Beach to those in areas offers locksmith services promptly in emergency situations. They aim to help individuals facing locksmith needs. Here are some typical scenarios where an urgent locksmith in West Palm Beach might come to the rescue; Lockouts: If you find yourself locked out of your house the… Continue reading What does an emergency locksmith do?